Over the years, SA HotRods Magazine featured some incredible builds. Many of them, despite their engineering brilliance, never really got the spotlight they deserved. This one is no exception — a 1972 Ford Escort Mk2 Panel Van that has been turned completely inside out, with a full-fat V8 mounted in the cargo bay.

By Brian B – Durban

Let that sink in: a mid-mounted V8 in a humble Escort van.

The man behind the madness is Bob Richardson from Howick in the Natal Midlands — a quiet little town where you’d expect to find tea gardens, not fire-breathing monsters lurking in panel vans. Bob, who previously owned a Ford GT40, had a clear vision when this project began: take the mid-engine magic of the GT40 and stuff it into an Escort. Just because he could.

He chose the panel van simply because he liked the way it looked — a blank canvas begging for something outrageous. A 1600 Kent-powered shell was sourced, and although it needed some rust repairs, the body was largely intact. No taillights or indicator lenses? No problem — Bob made his own. The van’s structure wasn’t going to cut it for what he had in mind, so he binned the original underpinnings and built his own chassis from scratch using 38x38x3mm square tubing. Bent, cut, and TIG-welded into a purpose-built skeleton, it laid the foundation for something far beyond Ford’s wildest dreams.

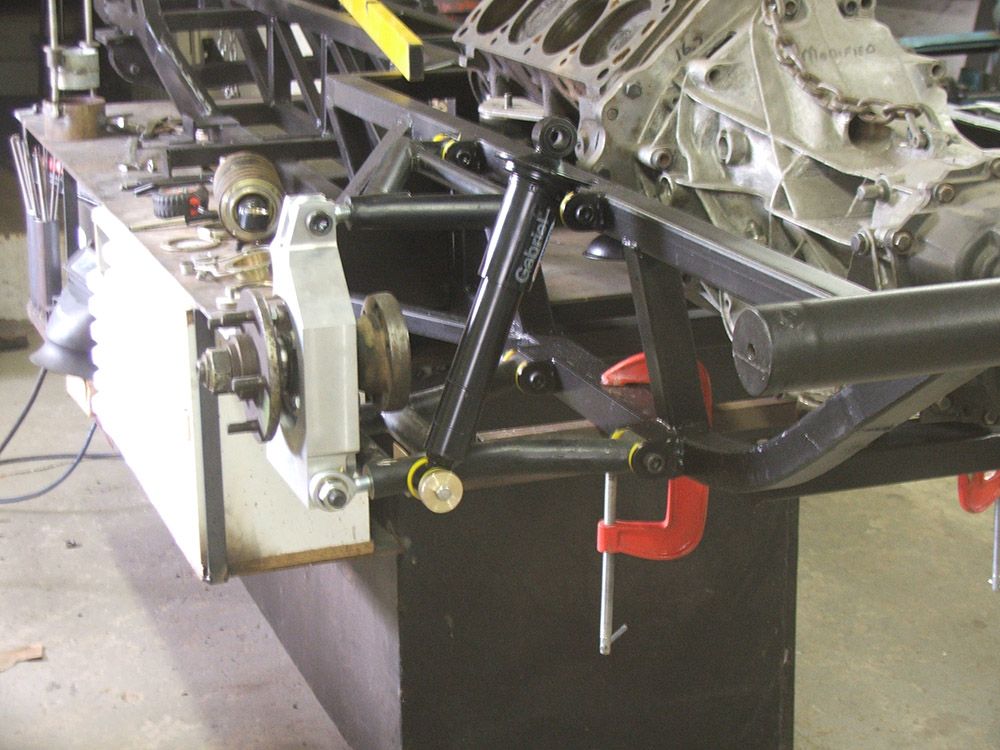

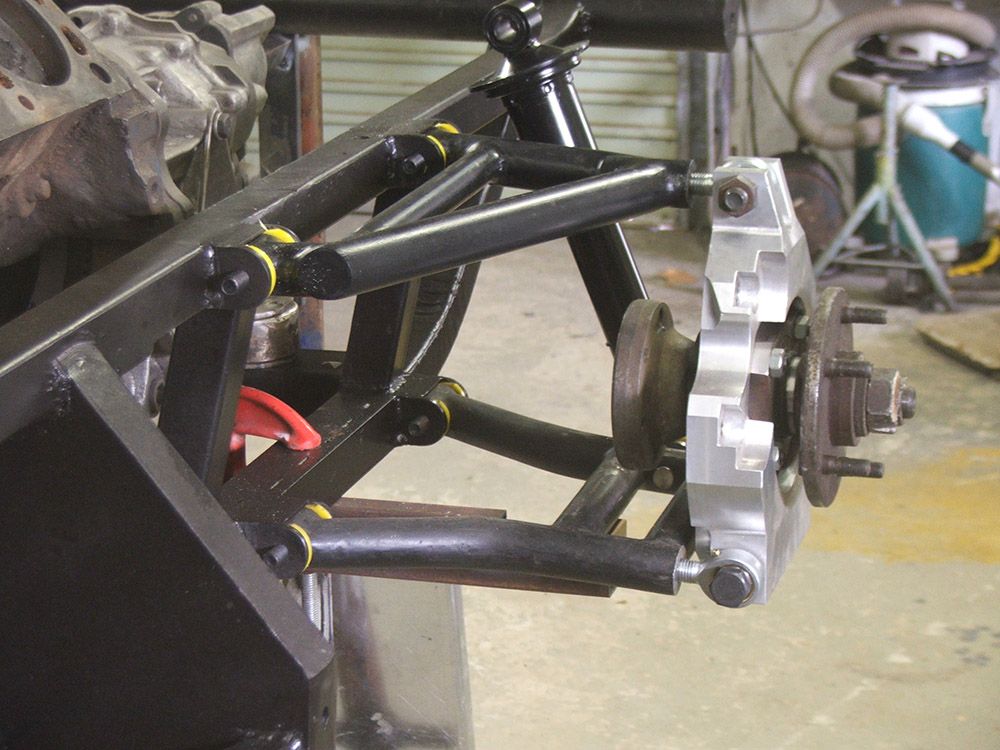

Up front, the original Escort struts and crossmember stayed, but that’s where the similarities ended. With custom hubs to accept larger bearings, vented Granada discs, and BMW four-pot calipers, Bob upgraded the braking power to match the impending horsepower. The whole front end was bolted to the chassis using rose joints, offering fully adjustable castor and camber.

The rear suspension is where things start getting spicy. Custom-machined billet aluminium uprights were built to house Granada hardware and adapted Audi driveshafts. These were connected via rose-jointed A-arms and finished off with Jaguar coilovers. The wheels? Chrome-finished and widened Mercedes steel rims, wrapped in 235/60 R15s up front and massive 275/60 R15s out back.

And powering this beast? A Ford 302 V8 that’s been built for proper performance. Skimmed heads and block, high-comp pistons, balanced internals, a rev ceiling of 8000rpm — this is no lazy lump. With gas-flowed heads, big valves, roller rockers, and custom headers that sweep up and over the motor like a vintage Grand Prix car, it’s making a proper 350hp. A Holley 600cfm carb sits on an Edelbrock intake, with an MSD ignition system making sure the fire stays lit.

Cooling all that muscle was a challenge in itself. A Cobra kit car radiator and electric fan replaced the stock Escort unit, with coolant piped via copper lines. Two huge fiberglass air vents sit just behind the doors, one feeding the engine bay and the other housing an oil cooler complete with its own fan. Custom Perspex louvered windows, rear door vents, and even roof scoops were added to draw in cool air and evacuate hot air from the tight quarters.

Yes, it’s hot and loud in the cab — and Bob doesn’t deny it. A thin Perspex window and an aluminium bulkhead are all that separate the driver from the snarling V8 behind him. A stainless steel catch tank, header tank, and a massive custom fuel tank now live where the original engine used to be, with a rose-jointed strut brace tying it all together.

Body mods were minimal but functional. Fiberglass arches were a nightmare to fit, according to Bob, but necessary to clear the wide rubber. The paintwork was handled by Kingsley Krog of CountriTech in Merrivale, with Bob laying down the stripes and logos himself. Once the mechanicals were done, an auto electrician came in to wire the beast up — no small task given the custom dash and switchgear.

Inside, it's still a work in progress. A simple console houses toggle switches, a start button, and fuse holders. The dash is stripped-down and functional — a white-faced Auto Gauge cluster reads oil pressure, temperature, RPMs, and volts, with a digital unit and warning lights sitting alongside. A MOMO wheel, leather buckets, black carpets, and stock door cards complete the stripped-down cockpit.

From start to finish, this build took Bob six years. He did nearly everything himself. And while the Escort still needs a few finishing touches inside, there's no denying that this is an engineering masterpiece. It’s wild, raw, and absurdly cool.

A mid-mounted V8 in a Ford Escort van? You can’t ignore that — and we never should.