A blend of drag racing power, GT Cup-inspired design and modern luxury featuring a twin-turbo big block and a custom steel widebody, “Doughboy” sets a new standard for bespoke muscle cars.

Fast Facts

- Equipped with a 2,800-horsepower capable twin-turbo 540 cubic-inch big block.

- Highly modified Art Morrison Ent. Chassis with C7 Corvette IFS Geometry with Michelin Sport Cup 2 tyres sized at 325/25R20 in the front and 345/25R20 in the rear.

- Assembled with 35 custom CNC and 3D-printed parts designed and manufactured in-house.

- Bespoke metal widebody designed and constructed with 3D-printing tech.

RANCHO SANTA MARGARITA, CALIF. (Nov. 5, 2024) – Blazin Rodz, a new team of young builders pushing the boundaries of innovation in the custom car world, presented its creation for the 2024 SEMA Show, a 1970 Chevrolet Chevelle dubbed “Doughboy.” Fusing the power of a drag car with the sleek aesthetic of a GT Cup car and the luxury of an exotic supercar, Doughboy exemplifies cutting-edge craftsmanship and revolutionary design. Powered by a twin-turbo Chevrolet-based big block delivering over 2,800 horsepower and built utilizing multiple 3D-based design and printing techniques, it’s a true marvel of engineering and performance. A new series surrounding the construction of Doughboy is available on YouTube and Roku TV, showcasing the state-of-the-art technology and techniques that go into building the car.

“Our goal with Doughboy was to create a vehicle that not only turns heads but offers a driving experience unlike any other,” said Riccardo Salatino, lead builder of Blazin Rodz. “We’ve pushed the boundaries in every aspect of this build, from the design to the engineering, and we’re excited to show the world what we’re capable of.”

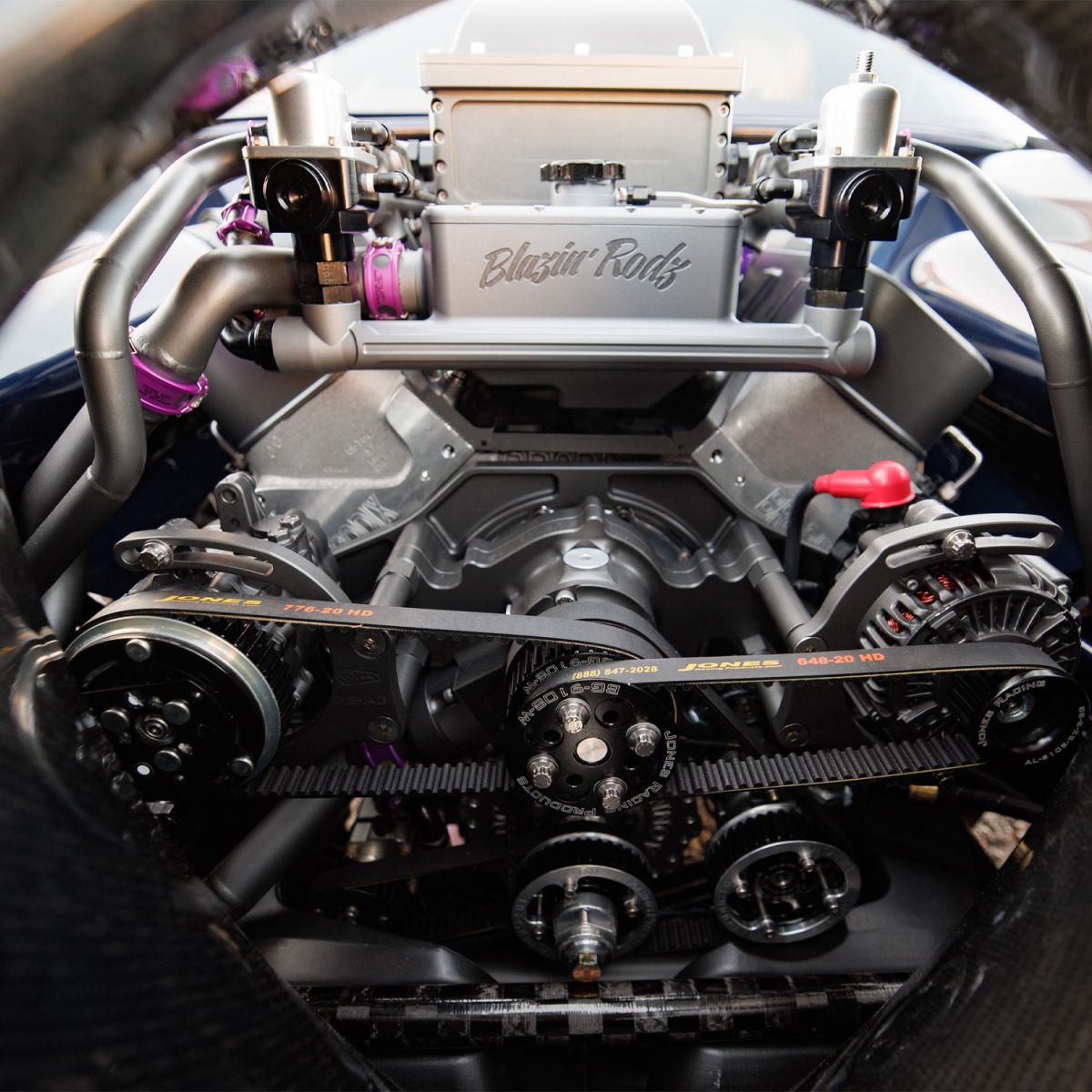

At the heart of Doughboy is an ACE Racing Engines-built 540 cubic-inch Brodix big block with forced induction from twin Precision 8385 Next Gen turbos. Custom 3D-printed carbon-fibre radiator ducts and heat exchanger outlets are incorporated into the air-to-water intercooler system. The in-house engineered intercooler system not only supports performance but also serves as the front core support for the grille while maintaining the original “V” shape of the Chevelle. The engine has been shifted back 15 inches, improving chassis balance for optimized handling on track. It’s equipped with dual 10-GPM Aeromotive Brushless fuel pumps in a rear-mounted custom billet fuel cell that doubles as a rear diffuser to improve aerodynamics.

The team has meticulously designed and manufactured every part of the engine bay, from the custom billet intake with integrated dual-purpose fuel rails to the billet valve covers designed to clear high-lift Crower roller rocker arms. The CAD-designed firewall was formed utilizing a new CNC technology to ensure a precise and high-quality surface finish, a technique unseen in most builds.

Doughboy sits on a heavily modified Art Morrison Enterprises chassis with Corvette C7 independent front suspension geometry, strengthened to support the massive power output. The fully custom front and rear suspension is made with a five-axis CNC unit using billet 7075-T6 aluminium and utilizes spherical uni-ball joints and rod ends for precise control and adjustability. JRI hydraulic coil-overs allow for on-the-fly fine-tuning, enhancing the car’s ability to adapt to different driving conditions on both the street and track.

Wilwood SX6R six-piston brake callipers finished in 24-karat gold provide stopping power. Kompression Wheels' custom 20x13 front and 20x15 rear billet three-piece wheels are wrapped in Michelin Sport Cup 2 tyres in 325/25R20 and 345/25R20, respectively.

Doughboy’s widebody is hand-sculpted and 3D-scanned for precise fitment and finished with Porsche’s factory Night Blue Metallic paint. Inspired by modern GT Cup cars, the body maintains the classic muscle car aesthetic of the 1970 Chevelle while incorporating contemporary elements like cleanly integrated side-exit exhausts, a carbon-fibre flat bottom and a custom 3D-printed front bumper with integrated air ducts. The rear of the vehicle features a carbon-fibre trunk lid with integrated cameras acting as turn signal indicators, further emphasizing Doughboy’s blend of vintage design with modern technology. Custom infinity taillights and shaved drip rails round out the exterior’s modern aesthetic.

Inside, Doughboy continues its fusion of form and function. The roll cage, crafted from 4130 chromoly tubing, is designed using CAD and CNC processes, while billet aluminium A and B pillars give it an exotic and race-inspired touch. A Motec C1812 display unit is integrated into the dash above a custom tilt steering column mated to an Audi R8 steering wheel, which allows quick access to all driving controls, including the paddle shifters and the ability to switch tuning maps on the fly. Crafted by Avant-Garde Design, the interior balances ruggedness with luxury, ensuring Doughboy is as comfortable as it is capable. The car also features a top-tier sound system to rival any high-end aftermarket setup, ensuring no detail was overlooked.

Finally, the engine management system is a Motec 150 powered by two Motec PDM 30 units, allowing the entire 16-volt system to work without using a single fuse or relay. Utilizing Deutsch Autosport connectors, the system is married by a mil-spec motorsports-grade wiring harness sealed front to back. Lifeline’s 360 Fire Suppression System manages safety for the interior, engine bay and fuel system.

To see every step of the build process, be sure to watch the premier episode of “Blazin Rodz: The Series” on YouTube and Roku TV now. See the crew work countless hours to accomplish their most extreme build yet, bringing a concept to reality in just 11 months. For more information on Doughboy or Blazin Rodz, visit www.BlazinRodz.com or check them out on Instagram.