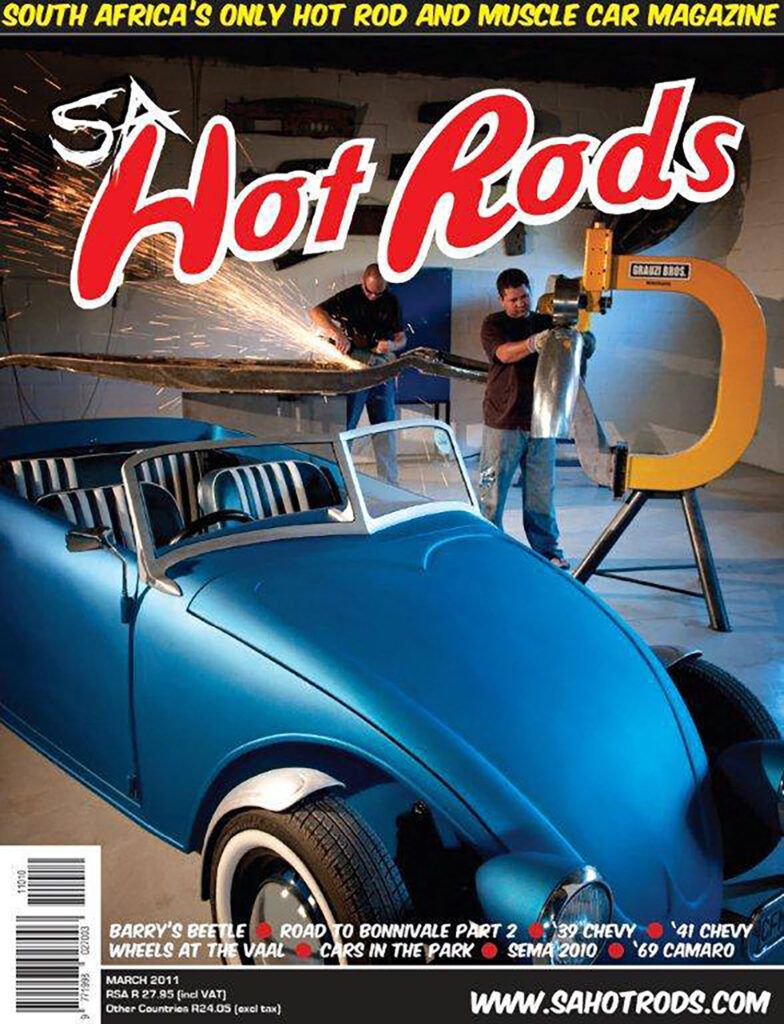

Most hotrod builders work from the approach of finding a car body in a style that they like (and often have to take what they get). A lot of the time this works out just fine and most of the classic, famous rods are well-known vehicles, perhaps only slightly altered from the original... but what if your ideas of style come from a little out of the left field if Ed Roth and Aaron Grote are among your heroes. Then you end up with the Volk Rodster.

Words: Fenton Stromberger,

Pics: Martin Van Niekerk

Enter Barry Ashmole from Stellenbosch, Cape Town. He is definitely no stranger to rodding, having been introduced to it by none other than Harry Corbett back in the mid-eighties, Barry brings a very different (some may say opinionated if they are being kind) approach to what is right, and wrong with the way we have always done things.

Some of his favourite topics of discussion are things like an overall design aesthetic, the importance of flow, and synergies between all of the different elements of a car. Approaching a build from this angle is more likely to yield a completed car that works on every level and that does not have a confused identity, says Barry.

I am as much a fan of the small block as anyone but I like to challenge the prevailing ideas of what constitutes a proper rod too.

Other areas where Barry differs strongly from the mainstream of rodding are to do with things like engine choice, configuration and what types of vehicles constitute a fair game. Maintaining a purists view of not mixing different styles or influences haphazardly, he is equally happy to throw the rule book out of the window when necessary. I am as much a fan of the small-block as anyone, but I like to challenge the prevailing ideas of what constitutes a proper rod too – just because you have a 350/350 and Jag suspension underneath it, doesn't mean it is done correctly quips the metal-shaping artist.

So, what could be more fitting for the first completed one-off metal-bodied rod out of his new shop (there are a pile of unfinished projects in various stages) than to start out with a humble VW Beetle?

Actually, it was never the initial intention to make this into what you see today, he says. As so many projects start out, this was only going to be a quick tidy-up of the lines of a car that Old Mill Rod & Custom had thrown together in about 24 hours.

Their little shop runabout was solid and reliable but pretty it was not! I got chatting with Simon one afternoon and offered to massage the metal a little to clean up the flow Barry reminisces. As so often seems to happen with me I soon had far more hours in it than I could justify and sure as hell was not going to present a bill for doing a friend a favour. I bought the car instead!

A quick revision of the direction he was going with the car, and work got underway in earnest. I never did any sketches or design studies of the car and I regret that a little, the only design work I did was a little lofting with a 5mm rod to check the lines, he tells us. The car was pretty much built as I went along, shaping each panel with an eye on those around it, as well as looking at the overall flow.

What he ended up with was 95% new sheet metal and a car about 200mm longer than a stock Beetle. It is also about 100mm higher in the doors. It was very important to Barry, even though every panel was made from scratch, that the car keep its identity. Everyone can see it is (or was) a Beetle, but only by comparing it with a standard one, do you begin to get an idea of the thought and work that went into creating this beauty.

Every part you see on this car was handmade in Barrys Stellenbosch workshop. He also shot the stunning metallic matt paint job but vowed never to do that again. I am no spray painter and with the final matt clearcoat, you only get one chance what comes out of the gun is what you get. There are no touch-ups! he laughs.

Every part you see on the car was handmade in Barrys Stellenbosch workshop.

A special thanks go to Jurgen at Grandslam Auto in Strand who did most of the mechanical work. Some earlier advice on the cooling by one or two experts led to an overheating situation that caused some serious mechanical issues. Jurgen took this on the chin and redid the work without asking for another cent. Not the kind of integrity and values that we are used to in this industry.

The upholstery was also done in record time by Sam Ferris, also in the Strand. The combination of white and blue vinyl looks great against the blue paint, and the matching Perspex and aluminium door handles and switches finish it off in style. I do still need to get around to building that banjo-style steering wheel I have just been having too much fun driving it Barry admits sheepishly. He also admits that although he built the car for his wife, he is the one who always grabs the keys despite having a few other options with way more horsepower in his garage!

So, is this a real hotrod or a glorified beach buggy? That is a matter of divided opinion, but one thing is for sure: It turns heads and attracts attention; it pushes the local envelope in terms of design and execution and gives an idea of what can be achieved with some forethought and a little hard work.