According to the VIN, this 1937 Nash Lafayette Coupe rolled off the line on Tuesday, 2nd February 1937—Groundhog Day. Coincidentally, it’s also the day I was born, 23 years later. When I found that out, I knew this car and I were meant to cross paths. And as soon as I got it home, I dove straight into the build.

By Marthinus Goosen | Photos: Lindsay Thompson

Originally from South Africa, I moved to the United States in 1996 and then to Canada in 2000. My family and I settled on a five-acre plot in the small town of Okotoks, Alberta. I was introduced to hot rodding back in 1983 by my brothers, Frik and Louis, and eventually built myself a ’35 Ford five-window coupe. Like any rodder worth his salt, I’m always scanning the horizon for the next potential project—especially after failing to bring my ’35 Ford over from SA.

The Nash showed up during a random trip to Bentley, Alberta, about 300km from Okotoks. We were actually there to check out a horse. But just off a rural road, I spotted a tarp-covered shape that screamed old coupe. I knocked on the nearest door, heart pounding. An elderly gentleman with a walker answered, clearly unimpressed. “I’m so sick and tired of all you people asking about that car!” he barked. But I wasn’t leaving without at least seeing it. We struck a deal: $2,500 and a bottle of South African Red Heart rum—something he remembered fondly. Luckily, I had a bottle on me.

Under that tarp was the shell of a 1937 Nash Lafayette coupe, complete with a tree-sized dent on the roof, no motor, no gearbox, and no front axle. But to me, it was perfect.

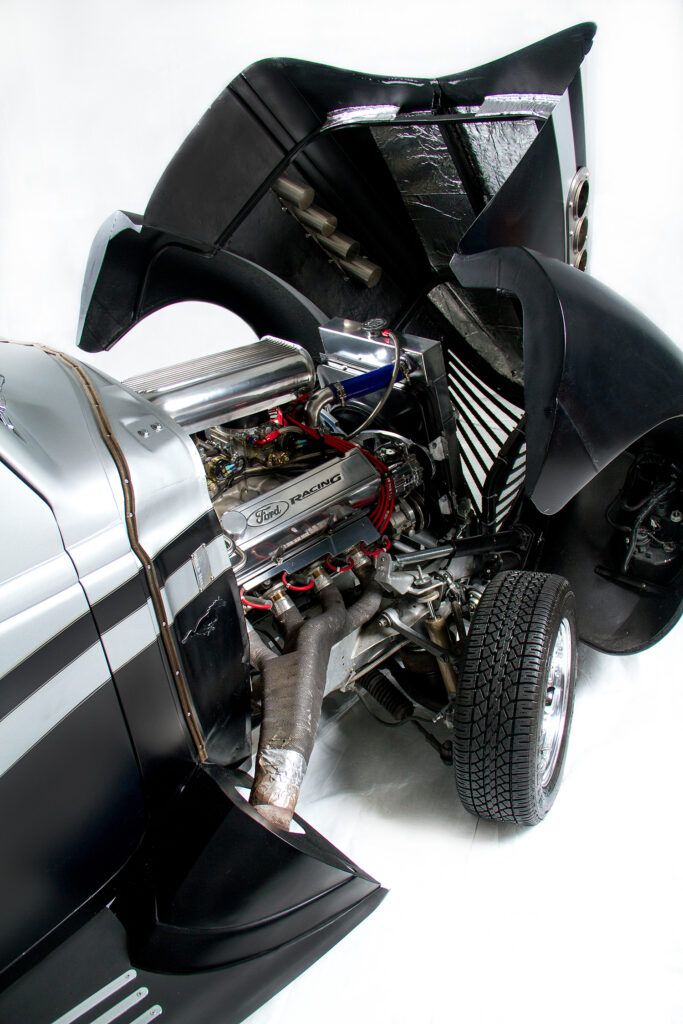

Once back in the garage, I decided to power it with something less expected than the usual Chevy swap. I found a running 1978 Mercury Grand Marquis that donated its 460ci Ford V8, C6 3-speed auto, and Ford 9-inch rear. At the time, I was working 850km away in the Fort McMurray oil sands on a 10-days-on, 4-days-off rotation—not ideal for progress. Needless to say, it was a slow burn.

Early on, I discovered the two front fenders didn’t match—one of those “oops” moments you only notice too late. I scoured local leads and eventually scored a correct set from a junkyard almost in my backyard. The grill, however, was another story. I couldn’t find one anywhere.

The chassis came first. I stripped the body off and installed the drivetrain, mounted a 1994 Jaguar front end, then added a four-link rear setup. Air suspension went in front and rear, with the compressor hidden beneath the rear floor and height control inside the cabin.

Building a hot rod in Canada has its quirks. Rodding culture here isn’t as massive as it is in the States, but the parts pipeline is fast—sometimes too fast. One click and it's shipped. The real challenge comes later, when you’re explaining those orders to your better half. My advice to new builders: set a budget with your boss lady before you start. Trust me—happy wife, happy life.

The headers and four-link were built from mail-order parts, but everything else I tracked down locally. With the 460 being as wide as a bar fridge, routing the exhaust through the frame was impossible. So I re-engineered the running boards, hid the pipes underneath, and had them exit just in front of the rear wheels. A rebuilt motor with twin 650 Holleys, a mild cam, and MSD ignition now delivers around 400hp—and it sounds glorious.

The C6 transmission got a 2500rpm stall converter, and the rear was rebuilt (twice—watch out for sharks out there). I’m planning to add an overdrive unit next to keep the 3.73 gears tolerable on long runs.

My goal is to drive this car all over North America—but winters here are brutal. We’re talking -35°C with wind chill pushing it into the -50s. So winter is garage season, and I’ve already started work on a 520ci stroker Ford motor targeting 600hp. Fingers crossed on that one—boss lady, please?

The sound system? Completely over the top. 1,100 watts, twin 10" subs, amps, and a flip-out DVD head unit. Eight speakers in total. And no, I don’t actually listen to it while driving. The real soundtrack is that deep Ford rumble.

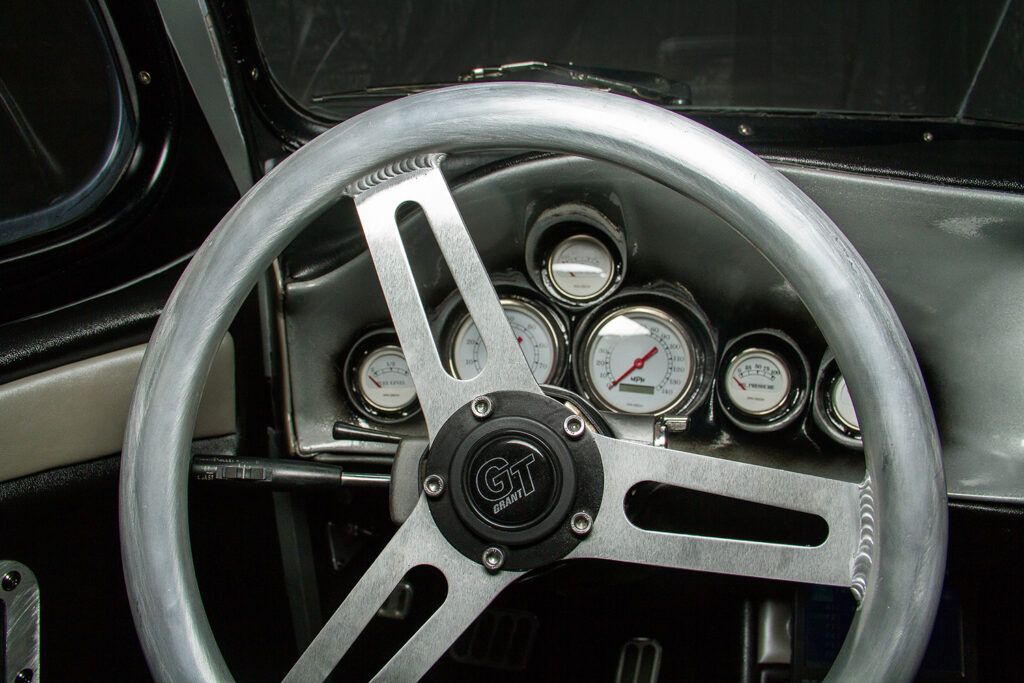

I went gadget-heavy on the build: remote doors, windows, tilt front end, and trunk—all powered by electric rams. At one point, I had more remotes for this car than for our entire house. I’m now working on a programmable logic controller just to keep them all straight.

The body’s all steel—except for the grill. After failing to find a replacement, I fitted a blank fibreglass 1937 Ford grill and custom-shaped the openings, finishing them with stainless mesh. It took major surgery on all the previously completed front-end metalwork. For lighting, I swapped out the massive factory buckets for Mini Cooper LED headlights and flush-mounted rears. Door handles, hinges, and quarter windows were shaved and smoothed for a clean, custom look.

The dash? Let’s just say the third time was the charm. I built it from scratch, housing a Vintage Air system and a full set of TPI Tech electronic gauges. It was a fight to get that HVAC system in, but you need it here—temps can swing from +20°C to -20°C in just hours.

Once the car passed inspection, I immediately took it out for a spin. Irma (yes, the boss lady again) asked if I had to roast the tyres every time. The answer, of course, is YES. Just wait till the 520 stroker is in—it’ll turn those 15" Centerlines into smoke on command.

The paint took years of prep. For a long time, the Nash wore primer in many shades of black and grey. But in 2010, I began driving it unfinished. In 2011, I entered it in a local Show & Shine with over 600 other hot rods—and won Best Custom, without even having final paint on it. That was motivation.

I was quoted $15,000 to paint it professionally, so I did it myself. My brother Louis flew out to help sand and offer guidance. I went with two-tone—satin black on the bottom, Mercedes silver on top, finished with a satin clear coat. The feedback has been overwhelmingly positive.

The interior? 1995 BMW seats, re-covered in German-sourced leather to match the look I wanted. I upholstered everything myself—seats, dash, panels—all done right here in my garage. The stainless fuel cell holds 147 litres, enough to get me to the next fuel stop, provided it’s not more than 350km away. But really—who builds a hot rod for fuel economy?

This build has been a long road, filled with late nights, missing parts, busted knuckles, and boss lady negotiations. But the end result is a car that turns heads, breaks necks, and brings a smile to my face every time I fire it up. And in the end, isn’t that the whole point?