1934 Chevrolet Rat Rod - Rattaaa

Jannie Viljoen is a experienced Rodder with years of building what ever he could find from Lotus 7 to bikes. My previous build was a 2JZ powered Lada Niva and because of the power and reliability of that iconic engine, this featured build also started off with the same engine. Since as far back as I can remember, I have always wanted to own a 1934 Chevrolet sedan explains Jannie. However, I always struggled to get his hands on one. One morning, four and half years ago, a good friend and customer of Jannie told him about an advert he saw in the Junk Mail.

Owner: Jannie Viljoen

Builders: JV Automotive

Location: Centurion Gauteng

Make and Model: 1934 Chevrolet Rat Rod

Various old car bodies were up for sale. He phoned the advertiser and found two body’s where for sale a four door sedan and a two door sedan, Jacques (Jannie Son) jumped in the car and raced to go see the bodies that was on the property of Pieter Bier – also an avid Hot Rodder. Unfortunately, Jannie was to late for the two door as it sold that morning. Not to be dishearten Jannie loading the four door on the trailer. The rust bucket was collected, and the project got off the ground.

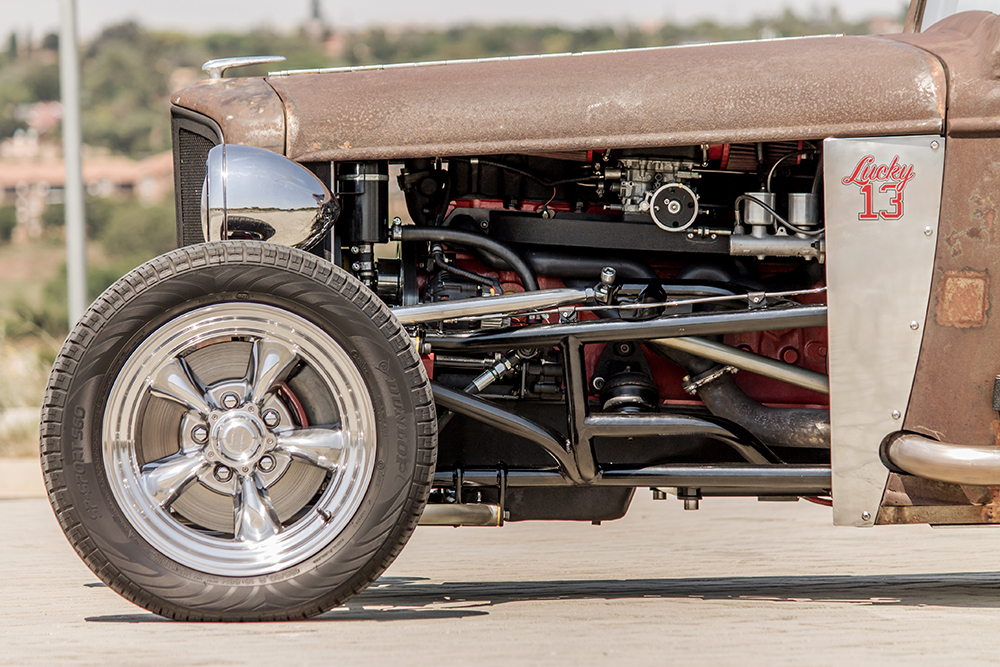

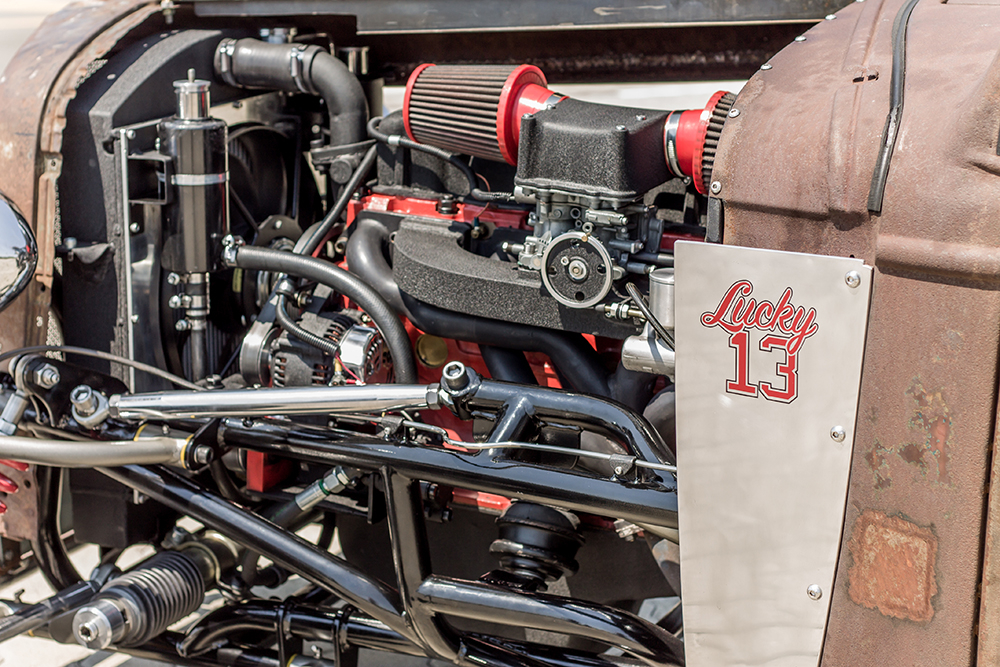

Jannie fell in love with the car from Factory Five in the USA. Factory Five is renown for building high end Rod and Cobras with tubular chassis instead of the tradition framed chassis. With his years of building cars under his belt he started the process of building the tubular chassis. First, a proper table and jig were made to start the assembly of what would become a lifelong dream come true. I also had to build my own tube bender as I wanted to use 38.3mm pipe Jannie explains.

I built a complete chassis and front suspension which needed a lot of custom-made parts and a large amount of inspiration. The original design for the front suspension came from the Lotus 7 however Jannie lengthened the upper and lower arms. The full front suspension was designed and built in house. The Spindles, Discs, calipers, power steering pump and steering rack was taken from a 2JZ Toyota.

The differential and rear suspension came from a Ford Falcon and the reason for this is that the 3.22 diff ratio works perfectly with the rest of the set up. The entire front suspension is custom built with spindles, discs, calipers and a power steering pump and rack donated from a 2JZ Toyota Soarer. Jannie’s goal was for the tubular chassis to be the main feature of the build. It had to be perfect every weld every bend, every cut then painted to in a gloss black. Next was the body.

There wasn’t much left of the original body. The body was cut in half and shortened. The back half of the rear doors was added to the front section of the front door. This was done as a 2-door car has longer doors than a 4 door car. The original doors skins were on the outside, so new inner skins had to be fabricated with electric windows (the only luxury fitting in the car) channels. Each replacement panel had to be welded and smoothed out. The new sections were then rubbed down with a mixture of vinegar and salt to get the rust cover beck. This 34 was not getting any paint. The original idea was to put a Totyota 2JZ motor in the Rod.

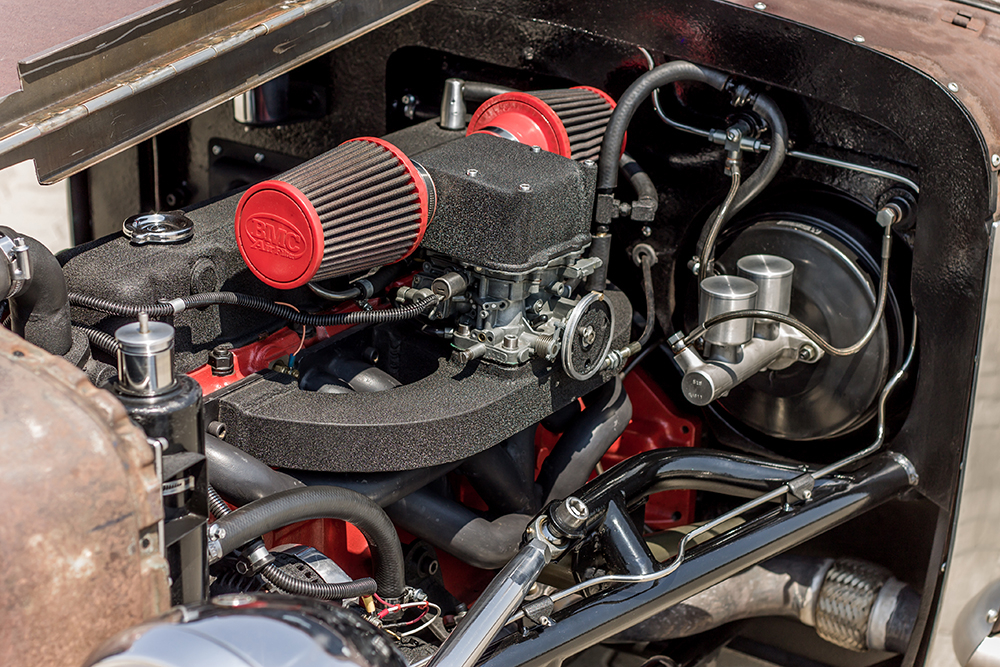

As the project moved along, the 2JZ was not the right motor for the look Jannie was going for, so that was ditched and in its place Jannie opted for a 4100 Chevrolet inline six motor. I then had to look for a 292ci. This was like looking for a needle in a haystack and I had to settle for a 250ci. The owner told me that the engine was completely rebuilt but that is a story for another day. The engine was stripped down and then handed to the very capable gents at Allan Y Brink Engineering. Under the watchful eye of Kevin, the engine was completely overhauled. It was re-sleeved and balanced with new 2-inch valves for the pistons and a serious camshaft was fitted. A new flywheel was ordered from RS Performance and a Toyota Dyna clutch kit was also thrown into the mix. The bellhousing was from Gilo Engineering, and I also added a brand new Toyota D4D gearbox.

“I ended up buying a complete car to serve as a donor for the project. I am the owner of a car service and repair shop; this project got a lot of attention from all my clients and they were constantly following the build progress.” Next was the interior, there wasn’t much to go in as Jannie wanted the frame on show in the car. Thoe fiberglass bucket seats were bought from Street Rod Factory and was then sent to Dennis from leather boys in Centurion to be covered.

Jannie had a set of 15-inch American Racing wheels laying around the shop. He contacted Hi-Tech Mag Repair and sent the wheels in to widened. I am so happy with the wheels Hi-Tech kept in contact, said it was the first time he had to cut American Racing wheels. The result was perfect. All they needed was some rubber narrowed front running 185x65x15 and fat at the back running 295x50x15.

The 1934 Chevy came out better tan expected. As the build went along I just wanted to make it better and better.

I would like to firstly thank my wife Amanda who backed and supported me through this build. I would also like to thank the following:

Kevin, Peter, Steve and all the guys at Allan Y Brink Engineering works, Dennis and Jeanine from Leather Boys for the upholstery, Wynand at Sandblasting Boys for the prep of the frame and Hydra Parts Centurion for all the brake fittings.