THE F100 HAULER THAT DEFIED THE ODDS: A Six-Wheeler Dream 40 Years in the Making

Some projects take a few months, others take a couple of years—but when you’re dealing with a lifelong dream, it’s not about the clock. It's about the journey. For brothers Frank and Heinrich Enslin, that journey began in 1982. Their mission? Build a six-wheeler pickup that would be a tribute to their friend, Tommy Jarret. They started strong, using a ‘56 Ford F100 steel body found on a farm in Bela Bela, but life had other plans. The project was shelved, leaving the brothers wondering whatever became of that steel body.

Reviving the Dream

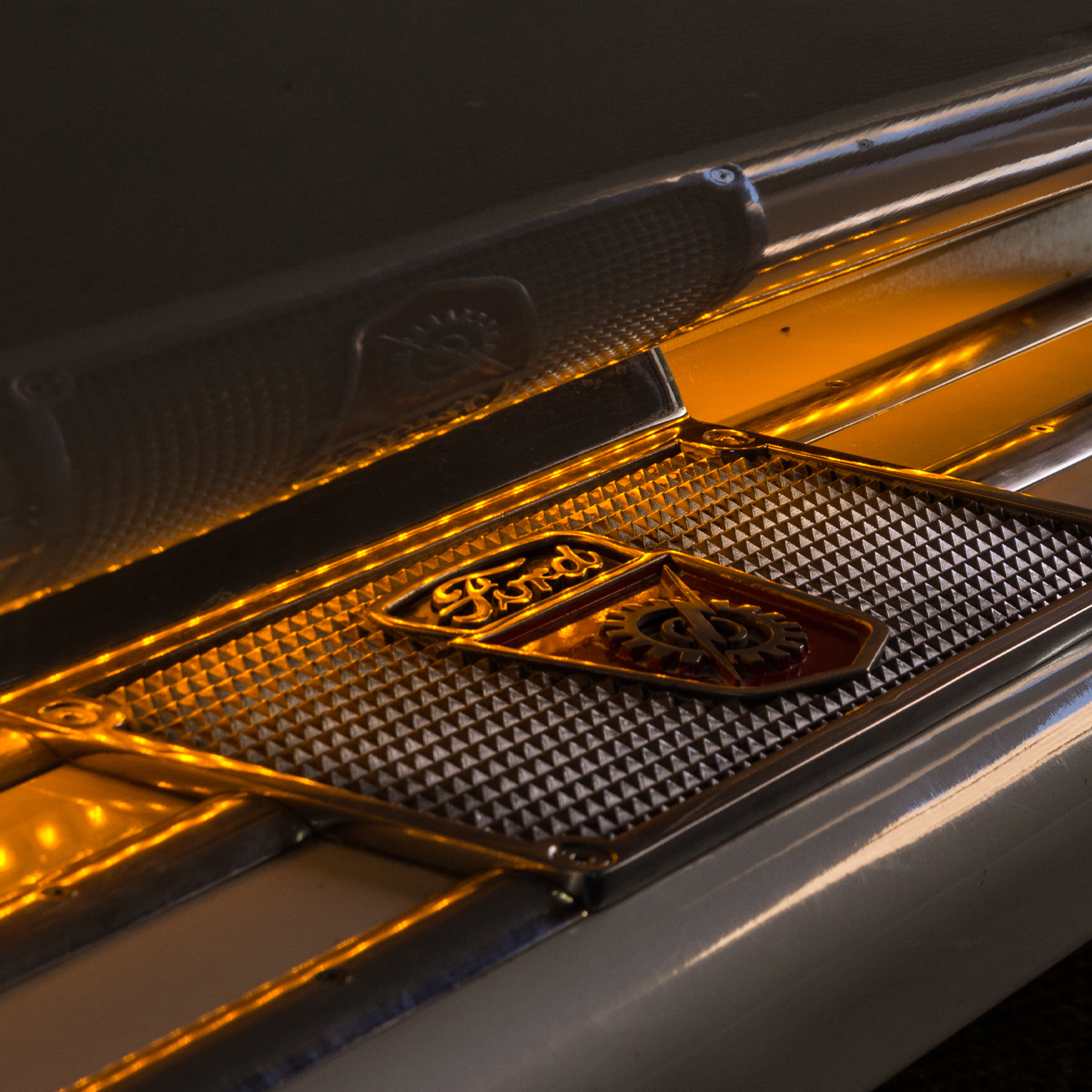

Fast forward to 2012. The brothers had spent the years honing their skills, with Heinrich Enslin recently completing a GT40 build. But the itch to finish their six-wheeler pickup had never gone away. During a hunt for a '50s Ford F100, they stumbled upon a fiberglass 1954 F100 replica body from the Hot Rod Factory in East London. The project was back on—this time with fiberglass and a renewed sense of determination.

The Build Begins

Building a hauler of this magnitude isn’t for the faint of heart. The brothers meticulously planned the project, from the drivetrain to the chassis. John Botha, a former GT40 Developments wizard, provided the chassis plans and CAD drawings. With Botha’s expertise and their own commitment to using Jaguar XJ6 geometry, the brothers sourced a front and two rear Jaguar suspensions. By mid-2014, with the plans in hand, they rolled up their sleeves and got to work.

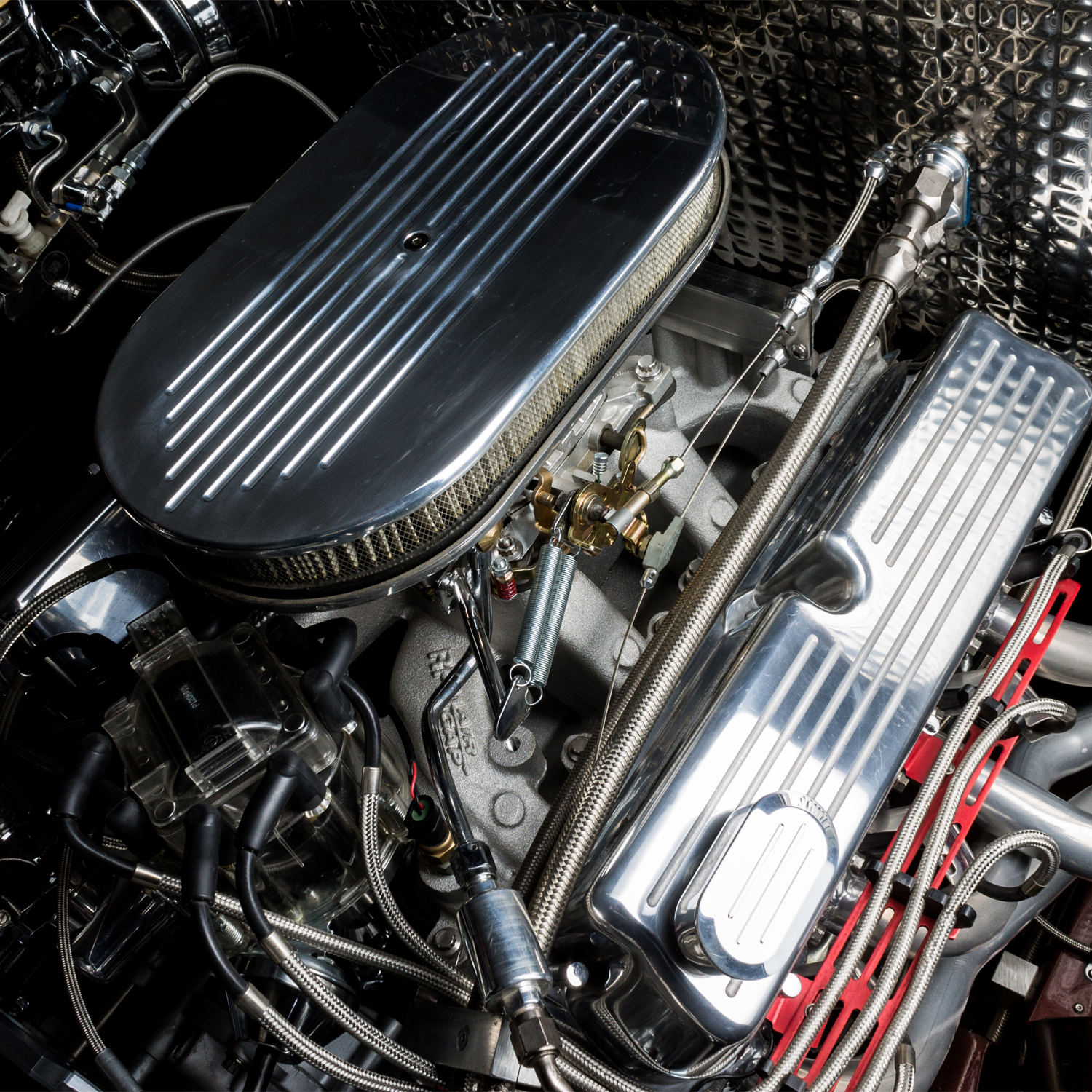

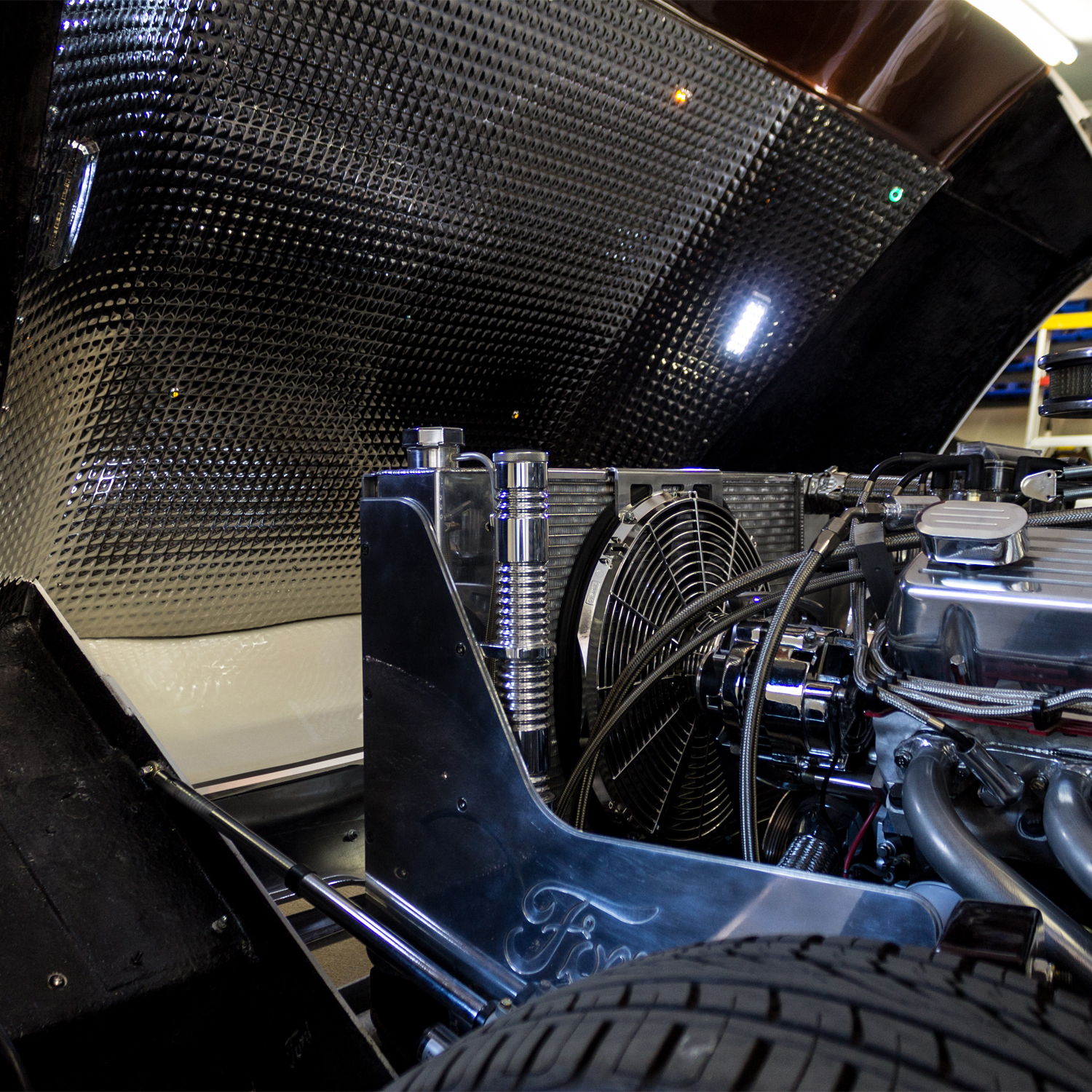

In the center of it all was the heart of the beast: a 351 Windsor V8 stroked to 408 cubic inches. Equipped with an Eagle forged crank, H-beam rods, and SRP forged pistons, this engine wasn't just about size—it was about power. With aluminum Ford Motorsport heads, a Comp Cams RV cam, and an Edelbrock Performer Air-Gap intake manifold topped with a Holley 600, the motor was ready to rip. Final assembly was completed by the legendary Mark Slooten, ensuring that every piece fit perfectly.

The Workshop of Dreams

In the spirit of true homebuilt hot rods, the entire project took place in the brothers' converted squash court workshop. Laser pointers, water levels, and hours of bolting, jigging, welding, and grinding went into ensuring the chassis was square and true. The chassis was stepped for added strength, and to keep things clean, every wire was neatly hidden inside the rectangular tubing.

Hydraulic Wizardry and Fiberglass Challenges

One of the most unique features of the hauler is the hydraulically lifting rear Bogie axle. This was no easy task—after hours of AutoCAD modeling and trial and error, the brothers finally cracked it using a hydraulic cylinder and Vesconite slide action. Planning out the fuel tank, battery box, and hydraulic pump while maintaining a clean look was another challenge, but the end result was worth every drop of sweat.

The wheel offsets were dialed in after they reshaped the original single-axle fiberglass load body. An inner steel frame was molded into the load body, allowing for a hydraulic tipper base that’s independent of the load body. And while the brothers designed the setup for future versatility (flatbeds for new projects, anyone?), they focused on getting the hauler's aesthetic just right.

Shaping the Body

Fiberglass was nothing new to the brothers, but this job came with its own set of headaches. The load body needed to be extended, and anyone who’s worked with fiberglass knows it has a memory of its own. Hours were spent laying, gelling, and molding the material—along with all the itching that comes with it. They added an eyebrow over the windscreen, molded in LED lights to give the front a menacing hauler look, and finished it off with three windscreen wipers for that extra touch of badass.

Steel wasn’t completely off the table either. The step sides were steel, designed to channel the rumble of the dual exhaust. Strips of polished aluminum gave the sides some dazzle, complementing the wooden floor in the load bed. A Curt hitch was installed, ready for future towing needs.

Electrifying the Beast

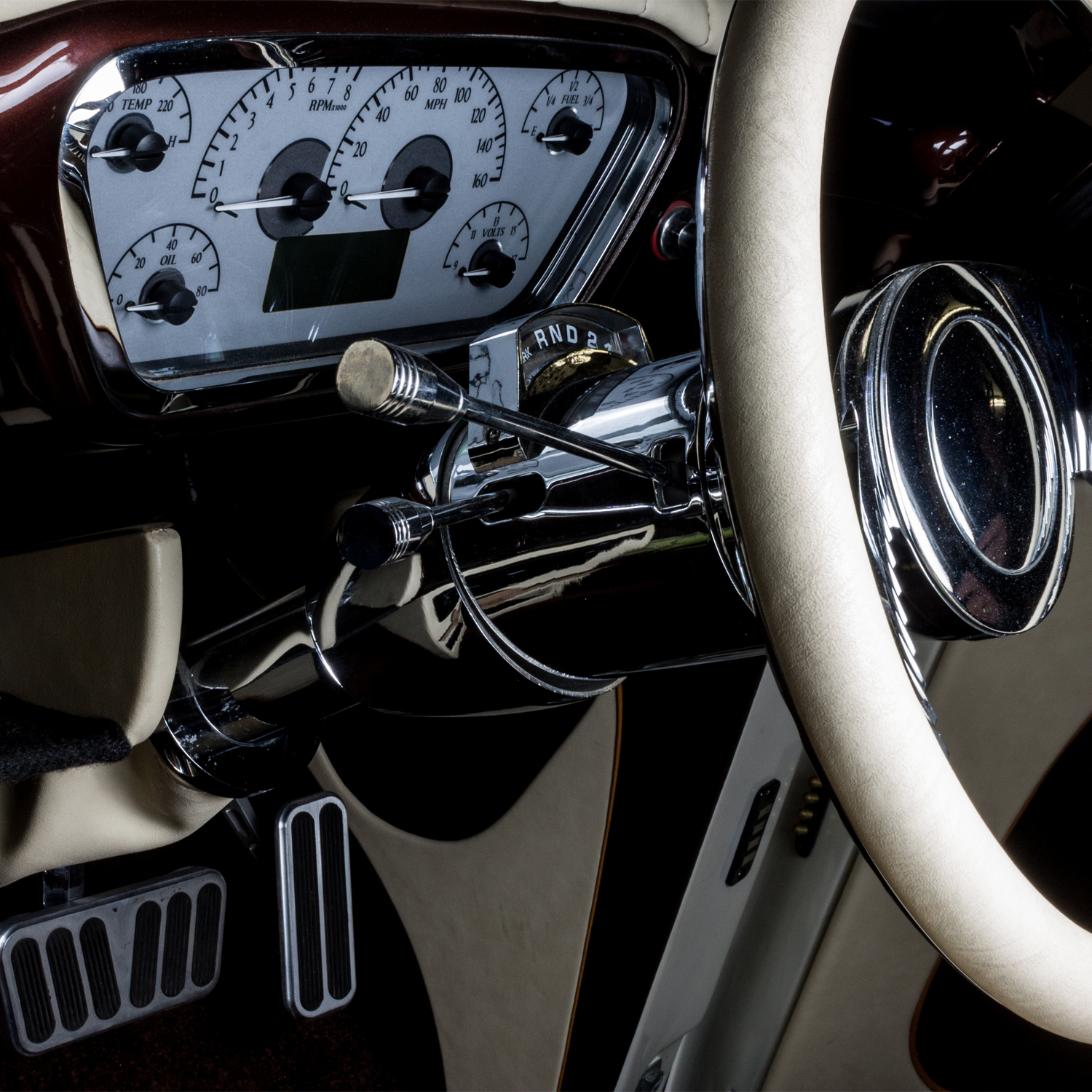

The electrical system was as high-tech as the rest of the build. Frank led the charge using Dakota Digital products, including a GPS speedometer module, electric hood locks, and an optic indicator for the hydraulic lift override. The goal? A clean, no-frills 1954 dash, modernized with a touch of tech.

Final Finish

After two and a half years, the project was finally complete. The brothers chose a stunning BMW brown metallic paint, accented with Lamborghini orange pinstripes and a Lexus pear white for contrast. Terrance Garland laid down the paint with precision, making the hauler a true head-turner.

Of course, no build is complete without a killer interior, and for that, the brothers turned to their trusted upholsterers, Mohammed and Moosa Shaik of MM Trimmers in Roodepoort. Having worked on countless projects together, the Shaik brothers knew exactly how to bring the dream to life. The custom upholstery and sound system are top-notch, adding the final touches to an already extraordinary build.

The Dream Lives On

What started as a dream over 40 years ago has finally become a reality. The F100 hauler is more than just a project—it’s a tribute to the brothers' relentless passion, patience, and ingenuity. From the stroked 408 under the hood to the hydraulically lifted Bogie axle, every inch of this build was crafted with love, skill, and a desire to create something truly one-of-a-kind.

In 2021, Heinrich Enslin made the difficult decision to sell the F100, closing a significant chapter in his life. That same year, Frank—along with his wife and one of his daughters—tragically passed away due to Covid, a loss that resonates deeply with all who knew their passion and commitment to the project.

Now based in Kalk Bay, Heinrich is settling into the scenic Cape life and diving into a new project: restoring a 1969 Opel GT. His dedication to unique builds and his enduring love for classic cars lives on, capturing the spirit of enthusiasts everywhere.

For more stories like Heinrich’s and builds that defy the odds, explore RestoMod.co.za’s features on iconic vehicles, incredible restorations, and the people who bring them to life.

Fast forward to 2012. The brothers had spent the years honing their skills, with Heinrich Enslin recently completing a GT40 build. But the itch to finish their six-wheeler pickup had never gone away. During a hunt for a '50s Ford F100, they stumbled upon a fiberglass 1954 F100 replica body from the Hot Rod Factory in East London. The project was back on—this time with fiberglass and a renewed sense of determination.

The Build Begins

Building a hauler of this magnitude isn’t for the faint of heart. The brothers meticulously planned the project, from the drivetrain to the chassis. John Botha, a former GT40 Developments wizard, provided the chassis plans and CAD drawings. With Botha’s expertise and their own commitment to using Jaguar XJ6 geometry, the brothers sourced a front and two rear Jaguar suspensions. By mid-2014, with the plans in hand, they rolled up their sleeves and got to work.

In the center of it all was the heart of the beast: a 351 Windsor V8 stroked to 408 cubic inches. Equipped with an Eagle forged crank, H-beam rods, and SRP forged pistons, this engine wasn't just about size—it was about power. With aluminum Ford Motorsport heads, a Comp Cams RV cam, and an Edelbrock Performer Air-Gap intake manifold topped with a Holley 600, the motor was ready to rip. Final assembly was completed by the legendary Mark Slooten, ensuring that every piece fit perfectly.

The Workshop of Dreams

In the spirit of true homebuilt hot rods, the entire project took place in the brothers' converted squash court workshop. Laser pointers, water levels, and hours of bolting, jigging, welding, and grinding went into ensuring the chassis was square and true. The chassis was stepped for added strength, and to keep things clean, every wire was neatly hidden inside the rectangular tubing.

Hydraulic Wizardry and Fiberglass Challenges

One of the most unique features of the hauler is the hydraulically lifting rear Bogie axle. This was no easy task—after hours of AutoCAD modeling and trial and error, the brothers finally cracked it using a hydraulic cylinder and Vesconite slide action. Planning out the fuel tank, battery box, and hydraulic pump while maintaining a clean look was another challenge, but the end result was worth every drop of sweat.

The wheel offsets were dialed in after they reshaped the original single-axle fiberglass load body. An inner steel frame was molded into the load body, allowing for a hydraulic tipper base that’s independent of the load body. And while the brothers designed the setup for future versatility (flatbeds for new projects, anyone?), they focused on getting the hauler's aesthetic just right.

Shaping the Body

Fiberglass was nothing new to the brothers, but this job came with its own set of headaches. The load body needed to be extended, and anyone who’s worked with fiberglass knows it has a memory of its own. Hours were spent laying, gelling, and molding the material—along with all the itching that comes with it. They added an eyebrow over the windscreen, molded in LED lights to give the front a menacing hauler look, and finished it off with three windscreen wipers for that extra touch of badass.

Steel wasn’t completely off the table either. The step sides were steel, designed to channel the rumble of the dual exhaust. Strips of polished aluminum gave the sides some dazzle, complementing the wooden floor in the load bed. A Curt hitch was installed, ready for future towing needs.

Electrifying the Beast

The electrical system was as high-tech as the rest of the build. Frank led the charge using Dakota Digital products, including a GPS speedometer module, electric hood locks, and an optic indicator for the hydraulic lift override. The goal? A clean, no-frills 1954 dash, modernized with a touch of tech.

Final Finish

After two and a half years, the project was finally complete. The brothers chose a stunning BMW brown metallic paint, accented with Lamborghini orange pinstripes and a Lexus pear white for contrast. Terrance Garland laid down the paint with precision, making the hauler a true head-turner.

Of course, no build is complete without a killer interior, and for that, the brothers turned to their trusted upholsterers, Mohammed and Moosa Shaik of MM Trimmers in Roodepoort. Having worked on countless projects together, the Shaik brothers knew exactly how to bring the dream to life. The custom upholstery and sound system are top-notch, adding the final touches to an already extraordinary build.

The Dream Lives On

What started as a dream over 40 years ago has finally become a reality. The F100 hauler is more than just a project—it’s a tribute to the brothers' relentless passion, patience, and ingenuity. From the stroked 408 under the hood to the hydraulically lifted Bogie axle, every inch of this build was crafted with love, skill, and a desire to create something truly one-of-a-kind.

In 2021, Heinrich Enslin made the difficult decision to sell the F100, closing a significant chapter in his life. That same year, Frank—along with his wife and one of his daughters—tragically passed away due to Covid, a loss that resonates deeply with all who knew their passion and commitment to the project.

Now based in Kalk Bay, Heinrich is settling into the scenic Cape life and diving into a new project: restoring a 1969 Opel GT. His dedication to unique builds and his enduring love for classic cars lives on, capturing the spirit of enthusiasts everywhere.

For more stories like Heinrich’s and builds that defy the odds, explore RestoMod.co.za’s features on iconic vehicles, incredible restorations, and the people who bring them to life.

Selling Price:

0.00

Sold:

Yes